Blog Published November 2, 2021 · Updated January 13, 2022 · 8 minute read

Building Back Better With Clean Materials Offers Big GHG Savings

Jake Higdon, John Milko, Stacy Smedley, & Sasha Stashwick

1/13/22 UPDATE: We updated our emissions savings estimates to reflect information we received after initial publication about the average carbon intensity of cement consumed domestically. Using a lower average carbon intensity in our assumptions resulted in a downward revision in our estimates. The updated values represent our best estimations given available information about the scope of use and embodied carbon content of concrete and steel in the U.S.

The Build Back Better Act offers a unique opportunity to ensure that billions in infrastructure investments go hand-in-hand with purchases of cleaner industrial building materials. The industrial sector produces the essential goods we need for modern society, like concrete and steel, but it is on track to become the top source of U.S. greenhouse gas (GHG) emissions within the decade. Cleaning up U.S. heavy industry is thus critical to achieving near-term climate targets, alongside the power, transportation, and buildings sectors. As a top purchaser of industrial materials like concrete and steel for the construction of roads, bridges, buildings, and other projects, the federal government can use its purchasing power to accelerate the transformation of U.S. industry by creating early markets for low carbon products. This is particularly true when federal procurement is paired with direct investments in industrial decarbonization and other complementary policies. Doing so will not only cut emissions but support good jobs and strengthen our manufacturing base.

To understand the potential climate impact of a robust investment in low carbon materials purchasing across the federal government, we derived an emissions savings estimate using real-world data on carbon intensity from the Embodied Carbon in Construction Calculator (EC3); federal procurement data from Global Efficiency Intelligence; and cost estimates from Energy Transitions Commission. Our estimate focused on cement and steel, which together account for roughly 15% of global GHG emissions. Nearly all federal procurement dollars spent on construction materials are spent on concrete (of which cement is the main and most carbon intensive ingredient) and steel.1

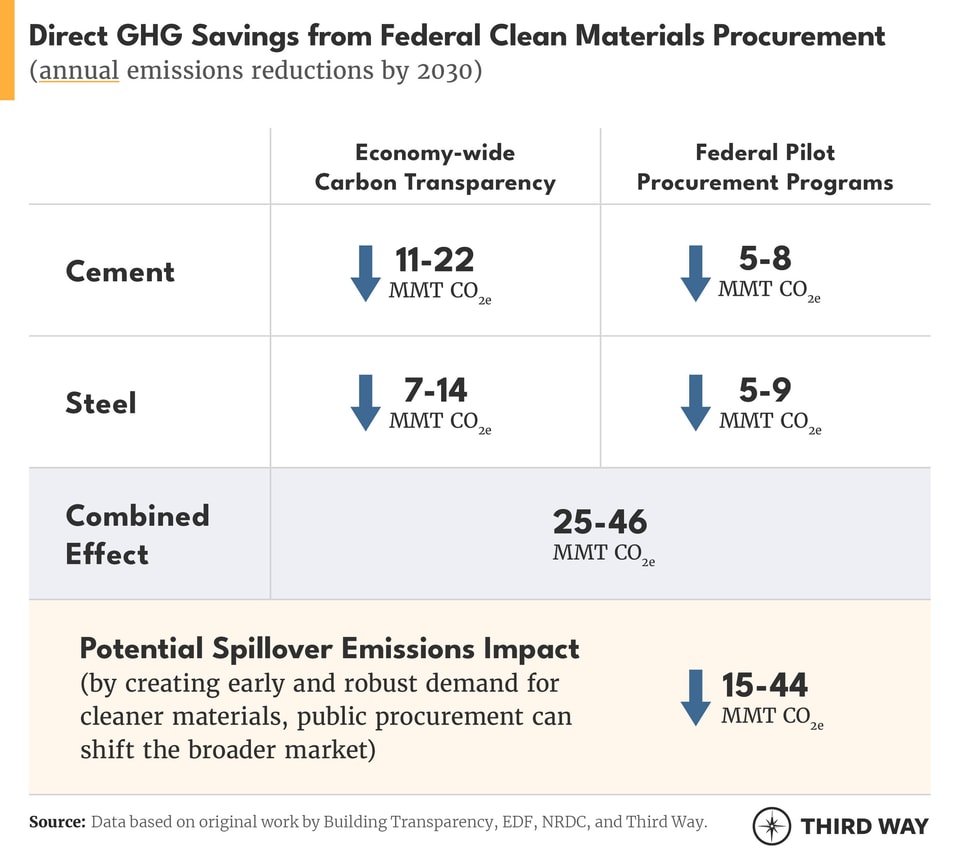

In the House version of the Build Back Better Act released last week, lawmakers provide more than $6 billion across federal agencies to support procurement of low carbon materials. We find that this funding, paired with grants to improve data on embodied carbon emissions in widely used construction materials like concrete, could save 25-46 million metric tons (MMT) of CO2 equivalent emissions annually by 2030 – or roughly 125-230 MMT CO2e in cumulative emissions savings, the metric that ultimately matters most for the climate, over the next decade. At the conservative 125 MMT estimate, that’s the equivalent of decommissioning 32 coal fired power plants, or taking 27 million cars off the road for an entire year.

How do these programs directly reduce industrial GHGs?

The graphic above summarizes our estimated annual CO2e emissions savings by 2030 under the two provisions Congress is considering: 1) transparency on embodied carbon in industrial building materials; and 2) low carbon materials procurement pilots at federal agencies.

The graphic also showcases potential additional emissions savings from positive spillovers in the private market.

1. Transparency

The first step in any clean procurement effort is getting high-quality data. Real-world evidence tells us that when presented with information about a product’s environmental impact, buyers and designers are making the cleaner choice.

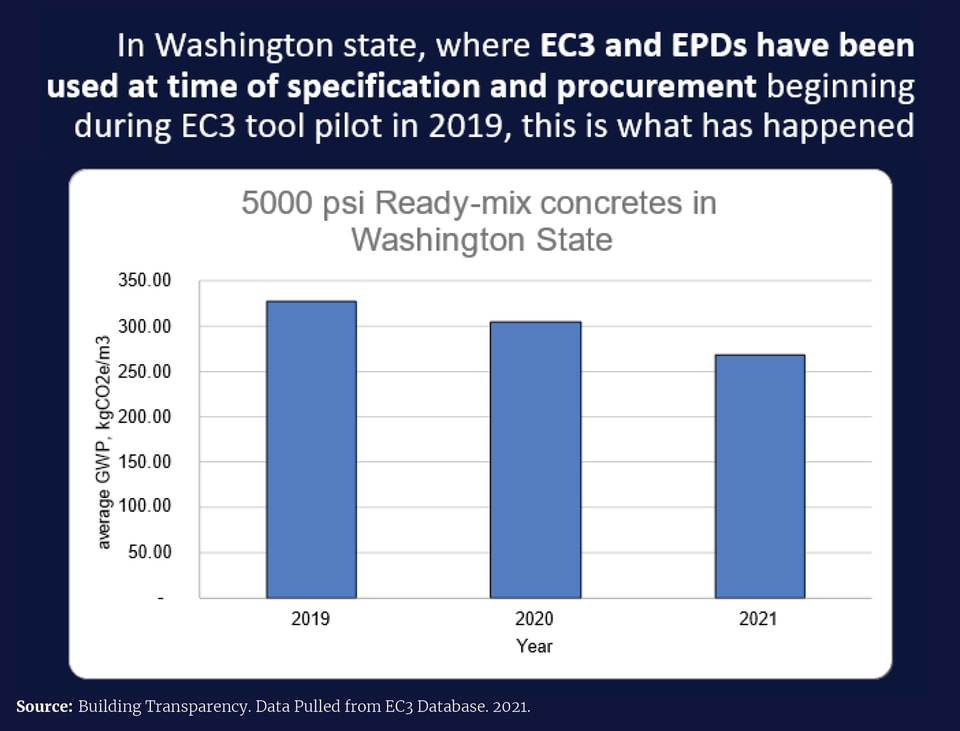

The House-passed Build Back Better Act included $250 million in grants to enable manufacturers of construction materials to disclose the embodied carbon of their products via Environmental Product Declarations (EPDs). EPDs are commonly used by the private and public sectors to inform sustainable building efforts. Passing such a program would help generate data critical to improving transparency in reporting the lifecycle GHG emissions associated with manufacturing a range of industrial products. Transparency alone has a demonstrated impact on reducing emissions. Recent case studies from Washington State show that requiring the disclosure of EPDs for concrete reduces embodied CO2e emissions by 20%. These reductions were largely driven by two major projects that simply required EPDs at time of bid, incentivizing concrete suppliers to compete on both cost and carbon emissions.

2. Low carbon materials procurement pilots across federal agencies

In addition to improving transparency, funding to support procurement of low carbon materials can a) accelerate the uptake of EPDs; and b) signal to manufacturers that there is a market for cleaner products. Congress is considering programs that could provide $6-7 billion over ten years to fund both premiums associated with purchasing low carbon materials and incentives to encourage adoption of low carbon materials by key industry stakeholders involved in federally funded construction projects. The programs would be housed at agencies that are major buyers of these materials, including the General Services Administration (GSA) and the Department of Transportation (DOT).

We estimate that $6-7 billion for low carbon materials procurement, combined with $250 million for establishing a robust EPD Assistance Program, could deliver

25-46

MMT CO

2e

in direct annual emissions savings by 2030.

#

Direct GHG savings are just the start

One reason many experts are in favor of clean procurement programs is because the purchasing power of governments can be a major market driver. By creating immediate demand for lower embodied carbon industrial goods, Congress can incentivize companies to adopt cleaner manufacturing processes and disclose their emissions, and those investments can spill over to other markets, where private sector companies, states, and foreign countries are increasingly clamoring for cleaner materials.

This has the potential to unlock even greater emissions savings for three key reasons:

- As more companies adopt cleaner manufacturing processes to compete for the large pool of federally funded construction business, those same manufacturers will be selling low-carbon materials to buyers in the private market alongside the public sector. Our analysis suggests this “indirect impact” will increase emissions savings compared to public construction projects alone. Applying our assumptions to the entire cement and steel industries, we estimate that total annual emissions savings in 2027 could range from ~55 to 91 MMt CO2e for the combined EPD and low carbon materials procurement program, roughly doubling its impact.

- As EPD uptake in additional sectors accelerates, more building materials could come under the pilot programs than just cement and steel, expanding its impact. Additional material categories with relatively high EPD penetration rates among domestic manufacturers include aluminum and glass. In the past year, the number of EPDs in EC3's free, open-access database have grown from roughly 600 to over 12,000 EPDs for non-concrete building products. For mix-specific concrete EPDs, the database has grown from roughly 8,000 EPDs to over 59,000.

- Complementary policies – like those in the House Build Back Better Act including funding for the Advanced Industrial Facilities Deployment Program and expanding advanced manufacturing tax credit (48C) eligibility to include industrial emissions reduction – can supercharge the impact of a procurement program, helping scale adoption of proven technologies that cut embodied emissions in widely used materials by 70% or more. This could be done by ensuring manufacturers of covered products can access funding to retool existing industrial facilities, as well as for the commercial demonstration and full-scale deployment of first in class ultra-low emissions technologies across key energy intensive manufacturing sectors. Developing and deploying these technologies for cement, steel and other types of industrial plants offers the prospect of commercializing game-changing climate solutions, akin to the innovation breakthrough represented by electric vehicles in the transportation sector or heat pumps in home heating.

Building towards a clean procurement future

Finally, funding transparency EPDs and procurement pilot programs through the FY22 budget reconciliation bill is just the beginning, not the end, of leveraging federal purchasing power to drive industrial decarbonization. Once we have a foundation of climate performance data and a track record of effective low carbon materials procurement, Congress should pass a federal Buy Clean standard to help make the U.S. industrial sector cleaner and more competitive. The programs under consideration today are essential groundwork towards that goal.

A Buy Clean standard should also include a high achievers market, so that federal procurement continues to not only raise the floor on climate performance for industries like cement and steel over time, but also incentivize continuous innovation and deeper decarbonization.

This will not only help the U.S. achieve our North Star climate goals, but also ensure the competitiveness of American manufacturing in a carbon constrained global economy. A recent report from the IEA, Net Zero by 2050, estimates that global demand for clean energy and sustainable infrastructure materials will reach $5 trillion per year by 2030. Because industrial decarbonization is being driven by technologies that exist today, we can invest now to cut emissions at our factories and help them make the low carbon industrial products the U.S. and the world will increasingly rely on.

For further information on embodied carbon reduction and related advocacy, see here:

LETTER: Letter supporting low-carbon materials procurement and industrial investments

RMI Report: Reducing Embodied Carbon in Buildings

Microsoft Whitepaper: Reducing Embodied Carbon in Construction